ABOUT US

OUR STRONG POINTS

Triada Druk is an offset printing house, a family business established by two brothers, Marek and Ryszard Śląski, in 1994. Since the very beginning the company has been operating, and growing, in the printing market, offering services in the most demanding fields: for food, pharmaceutical and cosmetic clients. Since its early beginnings, the printing house has worked with large, renowned European manufacturers and has enjoyed a stable position for many years, never sparing time and effort to further improve its products. The company’s key advantages:

OUR OFFER

ASK FOR FSC CERTIFIED PRODUCTS FSC®

We print according to ISO 12647-2 standard in the highest quality classes A and B (PSD certification by Fogra, a German graphic technology research association). In order to maintain the highest quality of our products we print on half format Heidelberg machines adapted for printing on specialized products:

Heidelberg SM74 (six colors) – CMYK + 2 colors,

Heidelberg CD74 (six colors) – CMYK + 2 colors + dispersive varnish.

We also employ cutting edge Heidelberg’s Image Control tools that allow us to continually monitor the production process and that guarantee constant, high quality of all our products. We print on paper sheets weighing from 50 to 550 g per sq m, of various texture, such as:

- label paper,

- chalk overlay paper,

- metallized paper,

- chromolux paper,

- dry embossed paper,

- synthetic paper,

- solid board,

- self-adhesive paper.

Our technologically advanced equipment allows us to apply a wide range of methods to process and enrich the prints. Over a dozen machines by Polar, Heidelberg, Iberica and Stahl are used to process the products. The print can be enriched in various ways to boost our products and show their exceptional workmanship and aesthetics:

- perforation,

- dry embossing,

- folding,

- folding and gluing,

- UV coating,

- dispersion coating,

- hot stamping – application of gold, silver, etc.

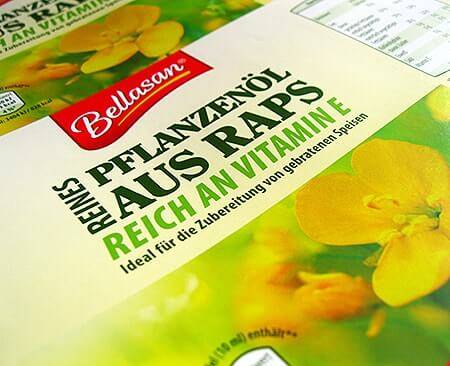

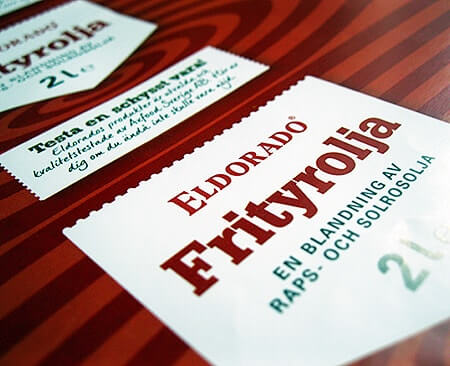

We focus on making specialized and enriched printing products for promoting food, pharmaceutical and cosmetic goods; our products can also be used for advertising other commodities, like alcoholic beverages, chemical agents, gardening supplies, interior decoration accessories, toys, etc. Thanks to our streamlined production process we can offer short lead times that the design process, printing and shipping to clients.

Labels:

- paper,

- self-adhesive sheets,

- synthetic paper,

- die cut (formed),

- perforated,

- UV coated, starting from 80 g / sq m,

- dispersion coated,

- hot stamped.

Booklets:

- glued,

- sewn,

- concertinaed,

- from 50 to 150 g/ sq m

- die cut (formed),

- perforated.

Packaging:

- made from solid board up to 550 g / sq m,

- dry embossed,

- UV coated,

- dispersion coated,

- hot stamped,

- film coated.

SELECTED CLIENTS

OUR CLIENTS

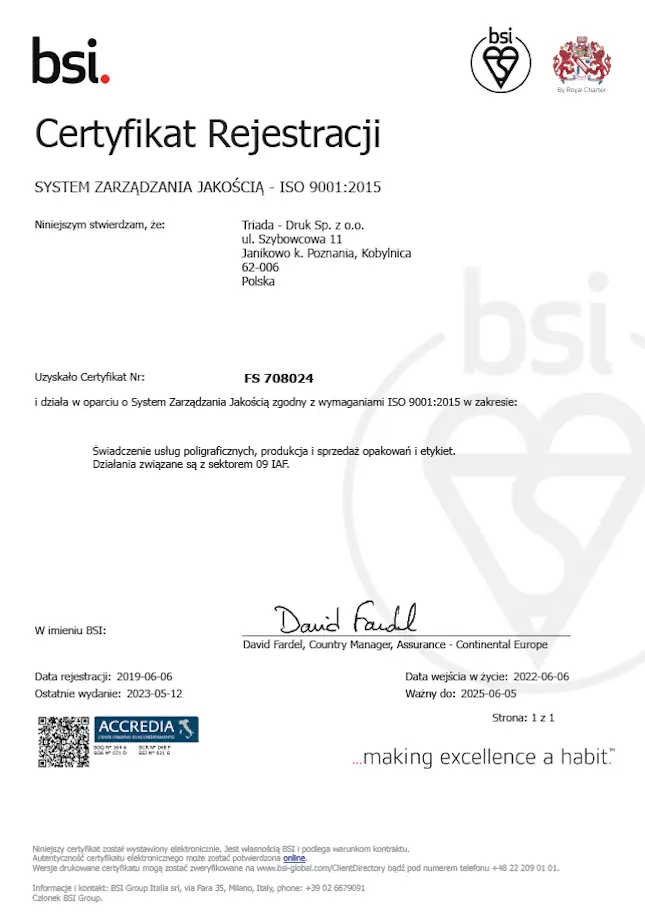

CERTYFIKATY

CERTIFICATE QUALITY MANAGEMENT SYSTEM ISO 9001:2015

We are a company certified by BSI (British Standard Institution) Group – the oldest standardization institution in the world (since 1901), operating under the “Royal Charter”, one of the founders and members of ISO (International Organization for Standardization). The implementation of the Quality Management System compliant with the ISO 9001: 2015 standard is a way for us to manage the organization. We operate in accordance with the principles of the implemented standard. This provides us with long-term cooperation with customers on a partnership basis, by providing products that meet their requirements.

CERTIFICATE FSC®

Aiming at constant development and care for the natural environment, in November 2015, We have become a company certified in the FSC® (Forest Stewardship Council®), the international certification system for forest management and wood products. The certificate confirms that the materials and products which we sell come from FSC®-certified forests as well as recycled materials and other controlled sources.

The Forest Stewardship Council® (FSC®) is a not-for-profit global organization, dedicated to promoting responsible forest management around the world. FSC® defines standards based on established principles of responsible management of forests with the support of environmental, social and economic stakeholders.

For more information, please visit www.fsc.org.